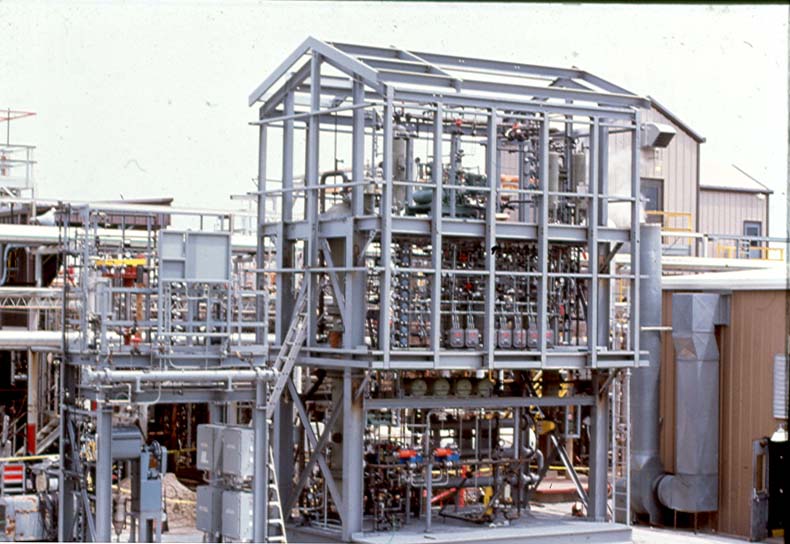

Pilot Plant Design & Fabrication: Putting Technology to the Test

Why do you need a pilot plant? You and your associates have developed a new process or product concept! It’s the Eureka moment! But now it’s time to “show me.” Where’s the proof? Where’s the data? That’s when a well-designed pilot plant is the essential tool that you need to validate your findings. A custom engineered pilot plant will give you the data you need to test your idea.

“If you are looking for a big opportunity, find a big problem.” Anon

Unitel’s principals first innovated what is today considered as the modern pilot plant industry back in 1974. We developed the concept of modular design and construction, and were the pioneers in the use of microcomputers for process control. We began this business and subsequently spawned several other companies around the world. In the meantime, every one of our projects has involved a journey into the unknown. However, working hand-in-hand with each customer, one fact is eminently clear – a well designed and constructed pilot plant can make the difference between success and failure. We began it all and we are still the leader of the pack.

Unitel’s principals first innovated what is today considered as the modern pilot plant industry back in 1974. We developed the concept of modular design and construction, and were the pioneers in the use of microcomputers for process control. We began this business and subsequently spawned several other companies around the world. In the meantime, every one of our projects has involved a journey into the unknown. However, working hand-in-hand with each customer, one fact is eminently clear – a well designed and constructed pilot plant can make the difference between success and failure. We began it all and we are still the leader of the pack.

Pilot Plant Projects

Of the hundreds of pilot plant projects undertaken by the Unitel team, some significant examples are noted below.

- 17 computer controlled hydrocracking and hydrotreating pilot plants for the Research Institute of Petroleum Processing (RIPP) in Beijing and Fushun in China

- Pilot plant to make fuel cell hydrogen from JP8 for the United States Army. System included sulfur treatment and catalytic autothermal reforming. Mission: To provide clean and “quiet” electric power in the battlefield.

- Pilot plant for the production of synthesis gas and hydrogen from infrastructure fuels using a process that combines catalytic auto-thermal reforming and water gas shift into a single integrated reactor – developed in collaboration with Argonne National Laboratory

- Geopressured aquifer simulation system for service with methane and brine at 20,000 psig and 350°F

- First computer-controlled jet fuel research system for the United States Air Force

- Fuel cell pilot plant for making hydrogen from JP-8 for the United States Army

- First direct coal liquefaction pilot plants in the United States and China

- Pilot plant for converting corn syrup into crystalline fructose

- Eight reactor hydrotreating pilot plant for catalyst testing, 2800 psig, 900°F

- First supercritical resid hydrotreater in the world

- Two reactor hydrotreating pilot plant for upgrading pyrolysis oil into oxygen-free fuels

- Multiple general purpose catalyst research systems. The Octave series by Unitel provides accurate performance data about catalysts – activity, conversion, selectivity, deactivation rates, longevity, regeneration, attrition and ruggedness. The Octave offers a choice of a packed tube reactor or the Spectrum gradientless reactor.

- Supercritical carbon dioxide pilot plant for the extraction of essential oils and fragrances from flowers and other botanical feedstocks

Kindly feel free to contact Unitel to receive more information about the above listed pilot plant projects or about the other hundreds systems that we have provided to 400+ major industrial firms and R&D organizations in 31+ countries around the world.

A well designed pilot plant must offer a high level of flexibility. Experimental requirements can change and the system must be able to operate under a wide range of conditions. The choice of materials for pilot plant construction is a critical factor and unattended operation is a highly desirable feature. Failure is not an option!

“Don’t be afraid to take a big step. You can’t cross a chasm in two small jumps.”

David Lloyd George