Conceptual Engineering

The Conceptual Engineering phase can generally be defined as a study phase where the initial technical concepts are further explored and defined and systematic documentation of the concepts are developed.

Process Scenario/Option Analysis

We work in close collaboration with the client to analyze different process scenarios and options for achieving project goals.

Experimentation

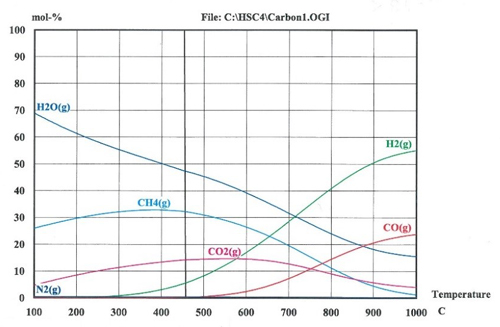

Kinetics, Equilibrium and Thermodynamics

A sound understanding of these three parameters is necessary to proceed with a systematic process design. We assist our clients to develop this information with detailed literature studies, research analysis and simulations.

Preliminary Process Simulation

Unitel Technologies has extensive experience in the use of process simulation software. Over the last 20 years, we have worked on a wide variety of projects and processes requiring process simulations. Our broad experience in process simulation ranges from petroleum refining to inorganic chemical syntheses to biomass based processes.

Unitel Technologies currently licenses the AspenONE Engineering suite which includes Aspen Plus and Aspen HYSYS. We have also utilized other software platforms including ChemCAD and Pro II. Unitel also uses the Outokumpu HSC Chemistry software to generate phase stability and reaction equilibrium data.

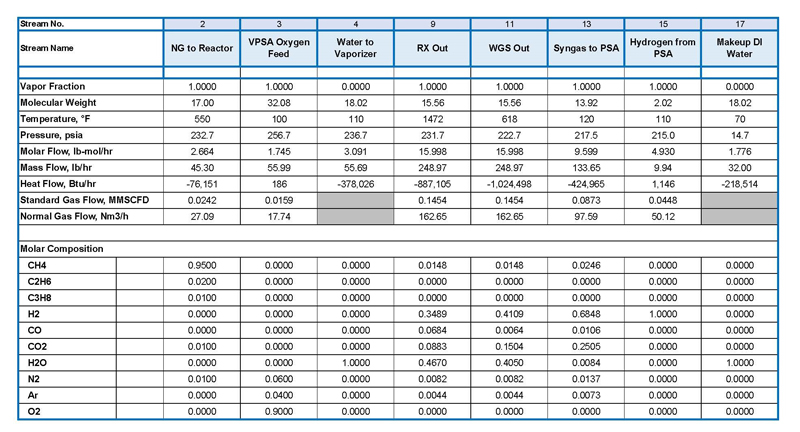

High Level Heat and Material Balance (HMB)

A natural product of conducting a process simulation is the generation of Heat & Material Balances. A typical study enables a quick analysis of process options to determine an approach for further optimization.

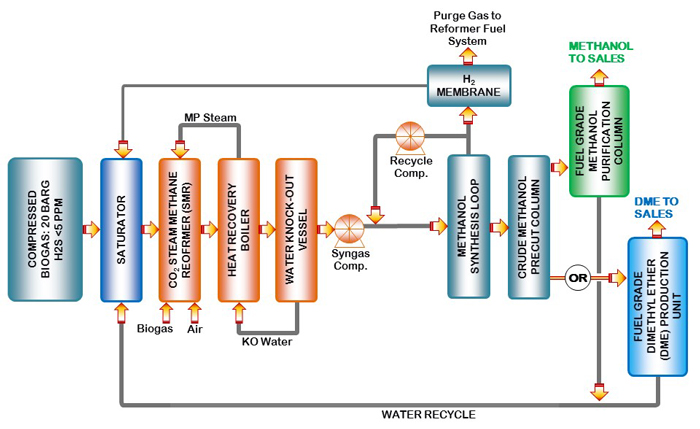

High Level Process Flow Diagrams (PFDs)

Process Flow Diagrams (PFDs) are frequently produced during the Conceptual Engineering phase to define and depict process options.

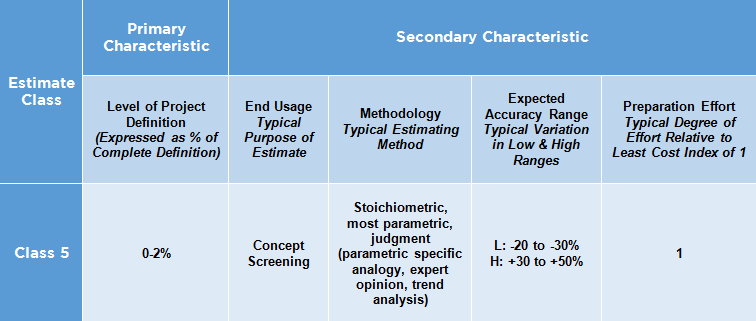

Cost Engineering – Association for the Advancement of Cost Engineering (AACE) Class 5 estimates

Cost estimating at a relatively low confidence level is typically carried out during the Conceptual Engineering phase to compare optional process scenarios and generate initial budget estimates to screen a potential project for cost viability.

Based upon the Association for the Advancement of Cost Engineering (AACE) cost estimate classification system a Class 5 estimate would be typical for the Conceptual Engineering Phase.

Unitel Technologies employs a number of methods and tools to efficiently develop cost estimates with available data and project information. Our knowledge and history with pilot plant, demo plant and other modular systems combined with our broad process industry experience provides us a rich database to develop cost estimates during early project phases in which the level of detailed information is limited. We use parametric models based on past experience at this accuracy range. We may also use equipment factored models employing our in-house major equipment data base and factoring methods combined with ASPEN Cost Estimator.